As the landscape of additive manufacturing continues to evolve, technologies like EBM technology and DLP technology are paving the way for advancements in precision manufacturing. At TCT Asia, these innovations are transforming industries, particularly in the realm of electronics and complex component production.

Understanding EBM Technology

Electron Beam Melting (EBM) is a powerful additive manufacturing method primarily utilized for metal parts. By using a focused beam of electrons to melt metal powder layer by layer, EBM allows for the creation of complex geometries that traditional manufacturing methods cannot achieve. This technology is particularly beneficial for producing high-performance components used in industries such as aerospace, automotive, and medical.

At TCT Asia, EBM technology will be showcased as a solution for manufacturers looking to enhance production efficiency while maintaining the structural integrity of their products. The ability to create intricate designs without the need for tooling significantly reduces lead times and material waste, making EBM a preferred choice for many industrial applications.

The Rise of DLP Technology

Digital Light Processing, DLP technology, on the other hand, employs a digital light projector to cure liquid resin layer by layer. This method is widely recognized for its speed and precision, making it suitable for a variety of applications, including jewelry, dental, and, increasingly, electronic components. DLP’s ability to produce high-resolution parts quickly allows manufacturers to iterate designs rapidly, which is essential in fast-paced markets.

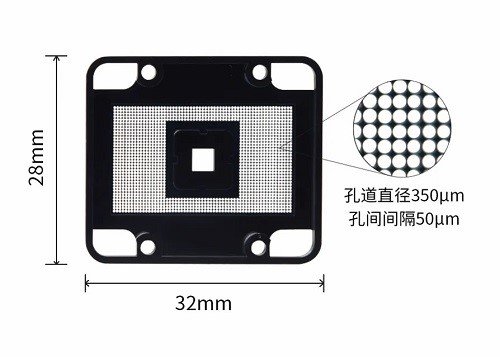

At TCT Asia, DLP technology will be highlighted through various demonstrations, showcasing its capability to produce intricate parts such as chip connectors, sensors, and other complex precision structures. The introduction of BMF's new Complex Precision Light Curing 3D Printing Technology represents a significant advancement in the field of precision electronics. This technology is specifically designed to meet the growing demand for small batch and scale manufacturing of precision instruments, fully addressing the needs of manufacturers requiring high-precision and complex connectors.

Applications in Precision Electronics

The combination of EBM and DLP technologies is particularly impactful in the field of precision electronics. As electronic devices become smaller and more complex, the demand for precise components such as chip connectors and sensors has surged. Both EBM and DLP technologies enable manufacturers to produce these components with unparalleled accuracy and efficiency.

For instance, DLP technology TCT Asia allows for the rapid production of intricate connectors that are essential for modern electronic devices. With the capability to print complex structures quickly, manufacturers can keep up with the fast-paced demands of the electronics market. Meanwhile, EBM technology TCT Asia can create durable parts that withstand the rigors of high-performance applications, making it a vital tool for industries that prioritize reliability and precision.

Enhancing Production Efficiency

Both EBM and DLP technologies significantly enhance production efficiency. By eliminating the need for traditional tooling and molds, manufacturers can reduce lead times and costs associated with production. This streamlined process is essential for meeting the demands of today's market, where rapid prototyping and quick turnaround times are crucial.

At TCT Asia, attendees will have the opportunity to explore these technologies firsthand, gaining insights into how they can be integrated into their own manufacturing processes. The event serves as a platform for networking and collaboration, allowing professionals to share knowledge and strategies for leveraging EBM and DLP technologies effectively.

Conclusion

In conclusion, the advancements in EBM technology and DLP technology showcased at TCT Asia are set to revolutionize the precision manufacturing landscape. By enabling the production of complex components with high efficiency and accuracy, these technologies are not only meeting the needs of manufacturers but also pushing the boundaries of what is possible in additive manufacturing. As TCT Asia approaches, the anticipation builds for the innovations that will shape the future of the industry.