As China continues to embrace Industry 4.0, 3D printing has emerged as a transformative technology, playing a crucial role in various sectors, including automotive manufacturing. With advancements like EBM technology and DLP technology, businesses are leveraging additive manufacturing to enhance productivity, reduce costs, and accelerate innovation. Events like TCT Asia serve as key platforms for showcasing these technologies and their applications.

Enabling Rapid Prototyping

One of the most significant advantages of 3D printing is its ability to facilitate rapid prototyping. This capability allows companies to quickly develop and test new designs, significantly shortening product development cycles. In the fast-paced global marketplace, where time-to-market is critical, Chinese businesses are increasingly adopting 3D printing to maintain a competitive edge.

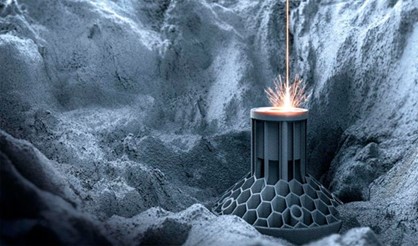

EBM technology is particularly beneficial in the prototyping phase for industries that require high-performance parts, such as automotive and aerospace. By utilizing electron beam melting, manufacturers can produce complex metal components with superior mechanical properties. This technology not only enhances the speed of prototyping but also ensures that the prototypes accurately reflect the final product’s performance characteristics.

On the other hand, DLP technology TCT Asia enables the rapid production of intricate parts with high precision. The process involves using a digital light projector to cure liquid resin layer by layer, allowing for the creation of complex geometries that traditional manufacturing methods cannot achieve. For the automotive industry, this means that manufacturers can quickly prototype components like brackets, housings, and connectors, leading to faster iteration and optimization of designs.

Automotive 3D Printing at TCT Asia

At TCT Asia, the spotlight will be on how automotive 3D printing is revolutionizing the automotive sector in China. With the increasing complexity of vehicle designs and the demand for customization, traditional manufacturing methods are often inadequate. 3D printing technologies like EBM and DLP provide the flexibility needed to address these challenges.

Automotive 3D printing TCT Asia will showcase a variety of applications, from producing lightweight components that improve fuel efficiency to creating intricate parts that enhance vehicle aesthetics and performance. By attending TCT Asia, industry professionals can explore the latest advancements in additive manufacturing, including new materials and techniques that can be applied in automotive production.

Bridging the Gap Between Design and Production

The integration of EBM technology and DLP technology into the prototyping phase helps bridge the gap between design and production. Traditional manufacturing often involves lengthy processes that delay product launches. In contrast, 3D printing allows for simultaneous design and testing, enabling companies to make adjustments in real time based on prototype performance.

This iterative approach is especially crucial in the automotive sector, where regulatory compliance and safety standards are stringent. Rapid prototyping facilitated by 3D printing ensures that manufacturers can quickly adapt to changing requirements and market trends, ultimately leading to more innovative and reliable products.

Conclusion

3D printing plays a pivotal role in shaping China’s Industry 4.0 landscape. With technologies like EBM technology and DLP technology on display at events like TCT Asia, businesses can gain insights into how these advancements can enhance their manufacturing processes. The ability to rapidly prototype and iterate designs is crucial for maintaining competitiveness in the global marketplace. As the automotive industry continues to evolve, TCT Asia will be an essential exibition for companies looking to innovate and thrive in this dynamic environment. Through these efforts, China is not just keeping pace with global trends but is also positioned to lead in the future of manufacturing.