3D printing technology has developed rapidly in recent years. It has moved from prototype modeling to actual industrial production. 3D printing creates intricate forms that are too advanced for traditional manufacturing. Technology and material advances cut 3D print costs and speed up production. This expands use in industries. The upcoming TCT 2024 event offers useful knowledge on this emergent domain’s prospective upgrades.

Types of 3D Printing Technologies

Several 3D print technologies exist based on the method and material utilized. Directed Energy Deposition (DED) focuses thermal energy like lasers during metal powder layer forming. Another technology is the Binder Jetting 3D printing. It involves depositing liquid binding agents like sand and metals layer by layer. This method allows multi-material printing for applications requiring different material properties in a single part.

Each technology has its own advantages and limitations. For example, DED 3D printing can produce very high-density metal parts, but the options for materials are limited. On the other hand, Binder Jetting 3D printing supports a wide variety of materials like sandstone, gypsum, and polymers, but the final part strength is lower than laser sintering. The right choice of 3D print technology depends on the specific part design and production requirements.

Common Application of 3D Printing Technology

3D printing is widely used in various industries due to design flexibility and the ability to produce complex parts. The following is an analysis of the 3D print technology advantages in various applications and sectors:

1. Aerospace

3D-printed aircraft parts are relatively lighter, with complex latticed internal structures and optimized outer shells. This reduces fuel costs significantly. Major aircraft manufacturers use topology optimization methods to 3D print brackets and mounts that attach engines. Their intricate geometric design improves load distribution and strength. The latest polymer and metal materials also withstand high operating temperatures. This is a major boost to safety and performance.

2. Automotive Manufacturing

Multiple plastic interior parts that comprise vents, handles, knobs, etc., are now being 3D printed as single parts. This simplifies in-car assembly lines and reduces the cost of installation. Car companies also leverage 3D scanning and printing to mass customize interior panels, dashboard shells, and even seats based on individual body scans.

3. Medical Field

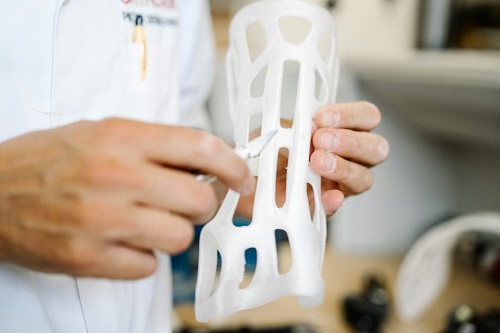

With patient MRI/CT scans, 3D printing enables precise anatomical replicas for complex surgeries. It reduces operation time through pre-operative practice on the models. Implants are also customized for each patient’s anatomy using biomedical materials. For example, porous 3D-printed implants promote better bone ingrowth. Surgical guides precisely position screws or drill bits intra-operatively. All this is actively improving treatment outcomes.

4. Architecture

Full 3D-printed houses show the potential to provide low-cost yet sustainable housing. Entire walls, floors, and shell structures can be printed onsite using concrete extrusion techniques with minimal wastage. Engineers are exploring rebar designs within such structures via the 3D print method. Furthermore, 3D printed scale models help clients visualize designs better for planning permission.

What to Expect of 3D Printing Technology from TCT 2024

TCT 2024 is a leading annual event in the 3D printing sector. It attracts thousands of attendees. The upcoming event (May 7-9) will showcase many new innovations, including some of the largest commercial 3D printers. TCT will also feature the latest multi-material 3D print equipment capable of combining multiple different materials.

Domain experts from major manufacturers will present cutting-edge research, such as large-format printing for various applications. Emerging areas being highlighted include 4D printing, programmable materials, bioprinting, and sustainable construction. Renowned futurists will discuss the technology roadmap expected to influence 3D printing across industries over the next decade. TCT 2024 provides a valuable platform for professionals to learn about the rapid evolution of 3D print applications from those driving the industry forward.

Conclusion

3D printing technology is transforming design and manufacturing across industries. The ability to produce fully functional final parts without assembling multiple components brings down costs and lead times. TCT 2024 will provide valuable insights into the future trends in 3D printing. It will showcase the latest case studies of applications in sectors like healthcare, aerospace, and mobility. It’s an ideal platform to understand how to best leverage this exciting technology within different sectors. Visit TCT Asia’s website to learn more about the upcoming conference and gain first-hand knowledge on the new opportunities 3D printing is unleashing.

Reference

[1] Okorie, O., Perveen, A., Talamona, D., & Kostas, K. (2023, December 13). Topology Optimization of an Aerospace Bracket: Numerical and Experimental Investigation. Materials (MDPI), 13(24), 13218. https://www.mdpi.com/2076-3417/13/24/13218

[2] Li, Z., Wang, Q., & Liu, G. (2022, March 27). A Review of 3D Printed Bone Implants. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9025296/

[3] Alkhalidi, A., & Hatuqay, D. (2020). Energy efficient 3D printed buildings: Material and techniques selection worldwide study. Science Direct,

Join us at TCT Asia, connect with industry innovators as you explore the entire AM ecosystem including design, materials, hardware, software, post-processing, and quality. 10,000+ professionals will unite to hear about the latest trends, explore the latest immersive AM technologies and find solutions to their AM challenges. Make sure you are there too.

TCT ASIA 2024

Tuesday 7th May 09:00 - 17:30

Wednesday 8th May 09:00 - 17:30

Thursday 9th May 09:00 - 15:00

NECC(Shanghai)7.1&8.1H