3D printing has rapidly advanced in recent years. Continued development of new materials is crucial for maximizing its capabilities and sustainability. The materials used determine what objects can be made and at what quality levels. While plastics are common, limitations exist. Developing improved properties through new 3D printing materials opens exciting applications.

Areas showing promise include green plastics, biopolymers, and high-performance composites. Advancing material options will enable the 3D printing of entire products beyond individual components. Progress relies on coordinated efforts in materials design and synthesis.

Progress in Research and Development of New 3D Printing Materials

Research into new 3D printing materials is yielding promising results. Green plastics made from agricultural byproducts or algae that are not only renewable but perform on par with traditional plastics are being developed. These green materials could replace many existing plastics used in low-stress 3D printed parts.

1. Green Materials

Green plastics show great potential as more sustainable, eco-friendly 3D printing alternatives to traditional oil-based plastics. These materials are derived from abundant and renewable plant-based resources like agricultural residues and algal biomass rather than finite fossil fuels. While offering comparable mechanical properties to plastics like PLA (Polylactic Acid), their production requires less energy and emits fewer greenhouse gases.

Green plastics could replace existing feedstocks for low-stress applications like housings, enclosures, and decorative items produced through 3D printing. On-demand manufacturing of such parts with green materials would significantly cut down on waste and reduce environmental impact compared to conventional manufacturing and distribution methods.

2. Bio-based Materials

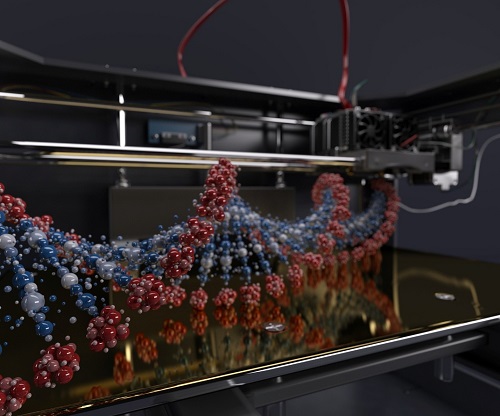

A variety of biologically derived polymers extracted efficiently from natural sources present opportunities for 3D printing. Starch, cellulose, collagen, and simple sugars can all be used as the basis for biopolymer feedstocks. These materials extracted from plants, algae, or otherwise are completely renewable.

In medicine, bio-based polymers allow high-resolution 3D bioprinting of living tissues and cells to regenerate skin, cartilage, and bone. They also enable custom, bioresorbable implants perfectly fitted to each patient through additive techniques. Beyond healthcare, bio-based plastics have applications as green alternatives for personalized prosthetics and implantable biosensors.

3. High-performance Materials

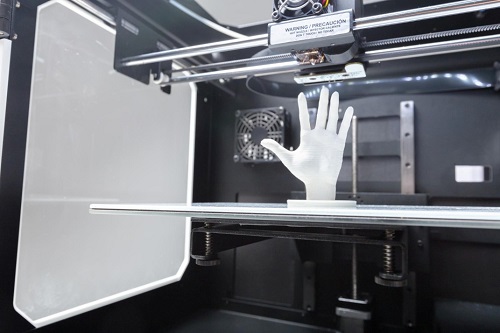

Advanced composites are enabling 3D printing for truly advanced industrial applications. Carbon fiber and glass-filled nylon materials provide strength exceeding regular nylons with resistance to elevated temperatures, which is useful in aerospace component prototyping. Conductive composites incorporating nickel coatings or graphene allow 3D structural electronics impossible through conventional circuit board assembly.

Meanwhile, aluminum and titanium composite filaments have begun driving additive manufacturing of functional metal parts for applications in automotive, medical, and defense sectors that would otherwise require CNC machining. These high-performance materials point to a future of customizable end-use products with complex embedded features through 3D printing.

Development Prospects and Challenges of New 3D Printing Materials

While new 3D printing materials are enhancing what the technology is capable of producing, challenges still need addressing for their development to be sustainable.

1. Development Prospects

As material varieties expand, 3D printing will penetrate more industries like automotive, medical, and consumer goods. Parts with embedded functions, self-assembling constructs, and living biological materials point to an exciting future. Standardized material specifications will streamline qualification and validation processes.

2. Challenges

High costs currently limit materials to specialty applications. Improving production efficiency and economies of scale can reduce prices. Some materials also require new post-processing steps. More research into recyclability after product lifecycles ends is important to maximize sustainability, too. Educating the standards community to qualify new 3D printing materials poses a coordination challenge as well.

Conclusion

Exploring and adopting new 3D printing materials is pivotal for how additive manufacturing shapes industries going forward. Sustainable alternatives to traditional plastics, biomedical applications, and novel high-performance composites demonstrate the potential of advances in this area. Going beyond prototyping to producing end-use parts will depend on continued work to expand material options.

The upcoming TCT 2024 will be the premier event for learning about new 3D printing trends. As the annual additive manufacturing conference, TCT gathers thousands of attendees seeking information directly from hundreds of exhibitors and expert speakers. Held in Shanghai from May 7-9, 2024, the event will showcase how cutting-edge materials enable novel design and production techniques. Attendees can gain industry insights and network with leaders advancing this technology. Visit TCT Asia’s website to discover event details, speakers, and exhibitors highlighting materials driving additive manufacturing forward.

Join us at TCT Asia, connect with industry innovators as you explore the entire AM ecosystem including design, materials, hardware, software, post-processing, and quality. 10,000+ professionals will unite to hear about the latest trends, explore the latest immersive AM technologies and find solutions to their AM challenges. Make sure you are there too.

TCT ASIA 2024

Tuesday 7th May 09:00 - 17:30

Wednesday 8th May 09:00 - 17:30

Thursday 9th May 09:00 - 15:00

NECC(Shanghai)7.1&8.1H