Since Xerox first bought Vader Systems and its liquid metal 3D printing division in 2019, the additive manufacturing (AM) sector has been awaiting the emergence of a niche dedicated to the drop-on-demand-style 3D printing of metals. Thanks to entrants like ValCUN and the purchase of Xerox’s additive division by ADDiTEC, the bubblings of such a subsegment began to appear. Now, as a new Cambridge, Massachusetts startup emerges from stealth with its own take on liquid metal 3D printing, it seems as though we can officially declare that the sector is here.

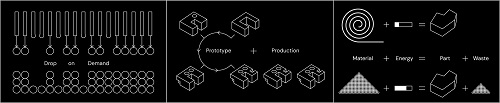

Dubbed Fluent Metal, the startup has successfully secured an additional $3.2 million in venture capital funding, bringing its total to $5.5 million. The round was led by Hong Kong-based VC fund E15 and saw participation from Boston’s Pillar VC, as well as several industry angels. While we discussed the firm in an article earlier this year, little had been made public about its tech. We now know that Fluent Metal has developed a drop-on-demand approach, which the company claims can offer unparalleled scalability, process tunability, and compatibility with a broad spectrum of metals, including high-value refractories. At the core of Fluent Metal’s technology is the ability to fabricate metal parts in a single-step process, significantly reducing variability and material waste. This method is not only energy-efficient but also eliminates the need for the extensive overhead typically associated with metal 3D printing technologies.

“Drop-on-demand technology is an elegant approach to create complex metal components,” said Peter Schmitt, CEO. “Whether it’s prototype iterations of an idea or production runs of a single part, Fluent Metal will provide customers with great operational and material flexibility. This freedom will unlock new creativity and problem solving abilities across industries.”

“As the manufacturing industry evolves in response to the changing needs of global supply chains and sustainability demands, we need novel approaches to drive creativity and expand our collective conception about what’s possible,” said Philip Liang, Managing Partner, E15. “In the near term, Fluent Metal will spark the imagination of designers, engineers, and technologists to consider how rapid, on-demand production of custom metal parts could transform their capabilities. At scale, this approach will revolutionize the entire footprint and direction of industrial manufacturing.”

Fluent Metal’s technology stands out for its functional capabilities, operational efficiency, and sustainability. The system employs wire as the starting material, enabling multi-metal printing and the creation of complex shapes, such as fully enclosed voids and internal channels, without generating waste. Designed for easy integration into existing manufacturing workflows, this approach negates the need for specialized clean rooms and simplifies material changeovers, enhancing machine uptime and safety.

The team behind Fluent is a particularly interesting one, given how many of its members hail from Desktop Metal (NYSE: DM) and MIT. Whereas CEO Peter Schmitt was Chief Designer there, CTO Matt McCambridge was a Senior Research Engineer that led a research and development team at the binder jetting firm. The CFO, Elizabeth Linardos, served as CFO at Desktop where she “made eight times the CEO’s total pay.”

Additionally, Fluent’s advisors include the likes of Zach Vader, founder of the aforementioned Vader Systems, and John Hart, who not only founded Desktop Metal, but also metal 3D printing startup VulcanForms. Complementing them on the board is Chris Bangle, who was the Chief of Design for BMW Group, where he was responsible for the BMW, MINI and Rolls-Royce motor cars.

In other words, this is a formidable crew with more than a few connections to existing players in the world of metal AM. For instance, Vader should have some insight into Fluent competitor ADDiTEC and its technology and all of the staff have a grasp of what sets liquid metal apart from other 3D printing technologies. Given the U.S. Navy’s existing use of Vader/Xerox/ADDiTEC for aluminum 3D printing, Fluent likely has a shot of earning its own military contracts. The placement of Chris Bangle on the board also suggests uses for the automotive sector and the likely development of aluminum for Fluent’s process.

As the nascent world of liquid metal AM takes off, it’s worth noting that, in addition to the already named firms in the subsegment, Fluent also has to face off against Mitsubishi, which launched a form of directed energy deposition (DED) described as “dot forming” AM that seems akin to liquid metal drop-on-demand. Access to what is being developed in China is difficult to obtain, but there have been poorly translated hints that one 3D printer manufacturing has created a “micro-droplet” technique for metal AM as well. Going forward, it will be interesting to see exactly how this all plays out and what sectors benefit from this quick form of metal 3D printing technology.

Join us at TCT Asia, connect with industry innovators as you explore the entire AM ecosystem including design, materials, hardware, software, post-processing, and quality. 10,000+ professionals will unite to hear about the latest trends, explore the latest immersive AM technologies and find solutions to their AM challenges. Make sure you are there too.

TCT ASIA 2024

Tuesday 7th May 09:00 - 17:30

Wednesday 8th May 09:00 - 17:30

Thursday 9th May 09:00 - 15:00

NECC(Shanghai)7.1&8.1H