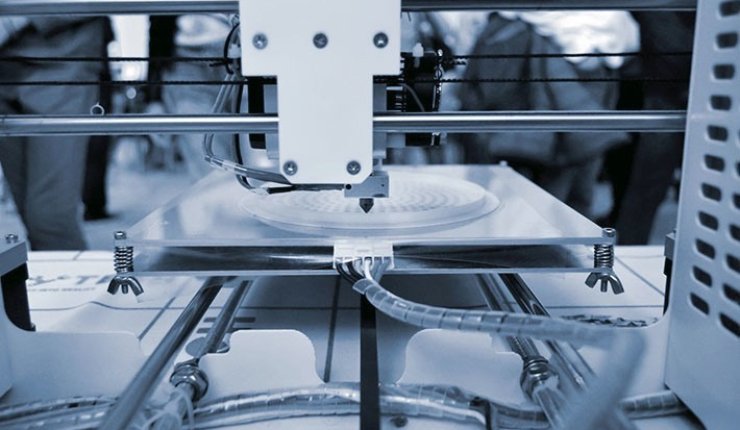

ASTM International’s additive manufacturing committee (F42) has developed two new standards that cover powder quality and aviation parts.

The first standard developed by the committee, F3571, is a guide for metal powder feedstock, intended to help manufacturers with quality control and assessing whether powder batches are within specification limits.

ASTM member Terry Stauffer said: “The proportion of these detrimental non-spherical particles will affect the flowability and spreadability of the feedstock, as well as the mechanical properties of the finished metal powder parts.”

The second standard, F3572, provides a part classification scheme that can serve as a consistent risk metric for additively manufactured parts in aviation, according to ASTM. Member and F42 Vice-Chair Chul Park said that this could serve processes such as inspection, testing, and qualification of the parts.

“It is important to understand the risk associated with AM usage by understanding its consequence of failure, including the loss of intended function,” said Park. “The information can be beneficial in establishing consistent processes relative to a defined risk scale.”

Park claims that further development and participation following this standard can help to accelerate the adoption of additive manufacturing technology. ASTM International says that both standards relate to the United Nations Sustainable Development goal #9 on resilient infrastructure, sustainable industrialisation, and innovation.

In the second half of 2022, ASTM was awarded funding from the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) to develop a roadmap for the guidance and adoption of advanced manufacturing technologies in the construction sector.