Meltio announced on November 8 a “giant step” towards facilitating the use of its metal 3D printing solutions. The Spanish company has unveiled two new innovations that aim to increase the reliability of metal part manufacturing for creating accuracy parts, the Meltio Horizon software and new Laser Calibration System.

Both technological solutions developed by Meltio’s engineering team are part of the company’s strategy to eliminate barriers that it says have in the past prevented metal additive manufacturing from having a significant presence in many industrial sectors. According to Meltio, it is now the perfect ally for these industries.

Meltio CEO Ángel Llavero said: “We have developed the Meltio Horizon software and the Laser Calibration System with the aim of facilitating the use of Meltio’s metal 3D printing technology for industries around the world. It should be noted that metal additive manufacturing has historically been associated with complex and expensive software, limited to the use of very few people because it was very specialised.”

Speaking about what the new solutions can achieve, Llavero added: “At Meltio, with the launch of our new software, we facilitate and shorten the learning time for you to democratise metal 3D printing so that your software is accessible and easy to use for many different profiles within a company. The Laser Calibration System will give industrial companies a new tool to be able to work with guaranteed reliability in the creation of their metal parts.”

Meltio Horizon is a proprietary toolpath generator software that works with the company’s 'plug-and-play' metal 3D printer, the Meltio M450, with its own features and custom-developed Meltio print and material profiles included. The new software solution is tailored to use the laser wire metal deposition process with the Meltio M450. Meltio says that until now, its users have been reliant on third party FFF slicers to prepare paths for the M450.

With the Meltio Horizon software, all of the material-related settings are directly in the slicing software, allowing for full control and a single profile. Meltio says that this also allows for more specialised printing profiles, with control of the laser and hot wire on a “per slicing feature” basis, instead of being set for the full part.

Currently, the Meltio Horizon software is only compatible with the Meltio M450 metal 3D printer.

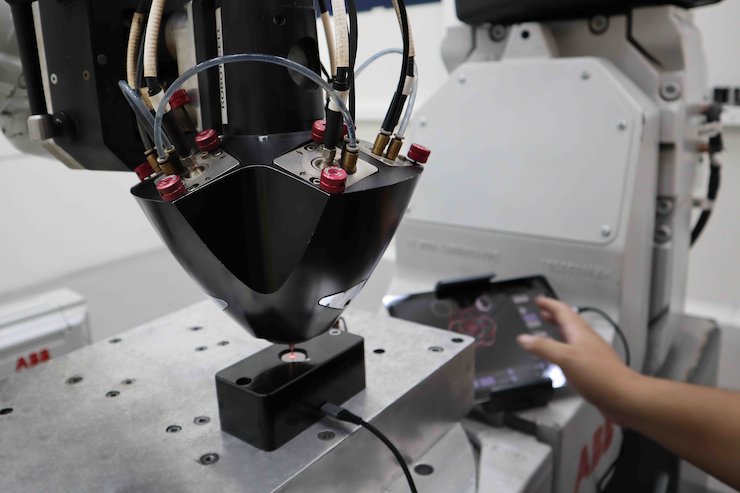

The new Laser Calibration System has been launched as an accessory kit to aid the reliability and use of the Meltio machines. The new system allows Meltio users to calibrate Meltio’s multi-laser deposition head accurately on all three of its metal 3D printing solutions.

The system consists of a laser alignment camera that has to be placed under the printhead, as it allows for a clear view of the focus point of the lasers. The camera is controlled using a portable controller, which also comes included in the kit as well as a software specifically designed to filter the camera image and guide the user to focus each laser on the most optimal point.

According to Meltio, its multi-laser metal 3D printing technology is based on the use of six lasers pointing to a mutual point to melt the welding wire that is fed through the centre of the deposition head. The lasers generate a high concentration of energy, called meltpool, which melts the metal feedstock. As a result, the welds beads are stacked on top of one another.

The alignment of each laser is critical to the process, they must hit the exact point where the energy is concentrated. Meltio says that the misalignment of the lasers leads to energy inefficiency and defects on the 3D printed parts, but the camera makes the calibration process easy to follow.