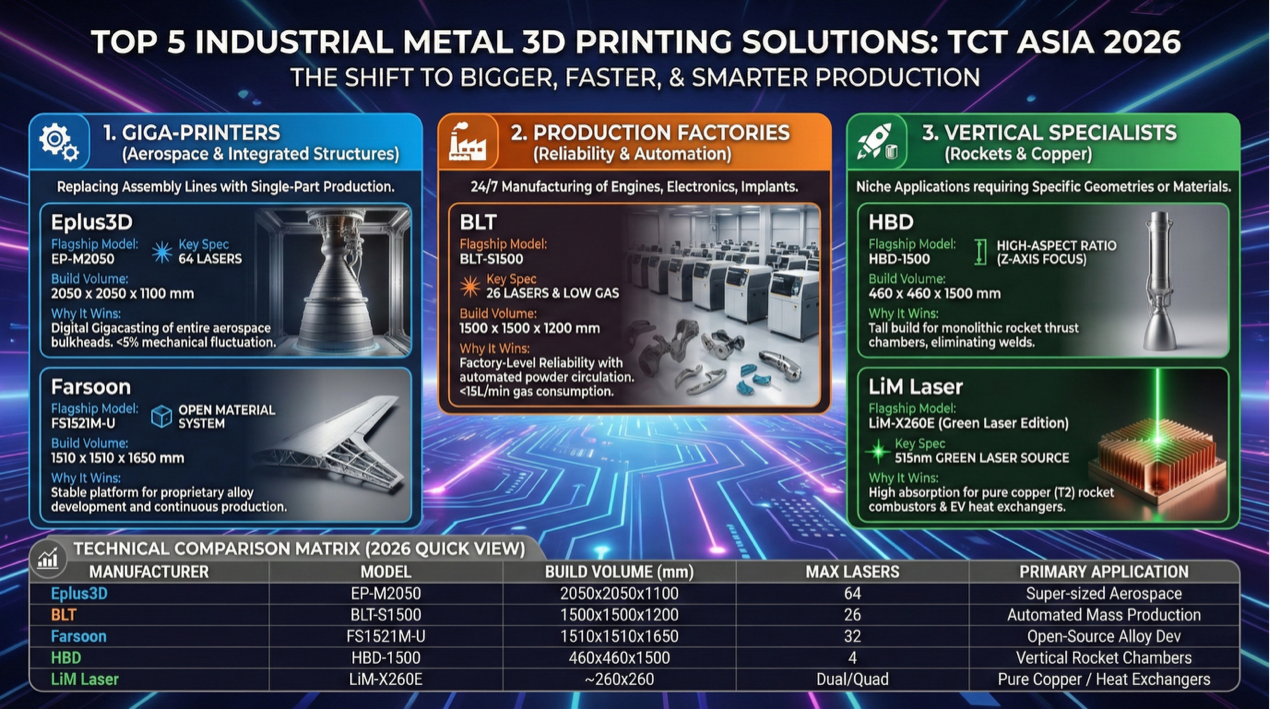

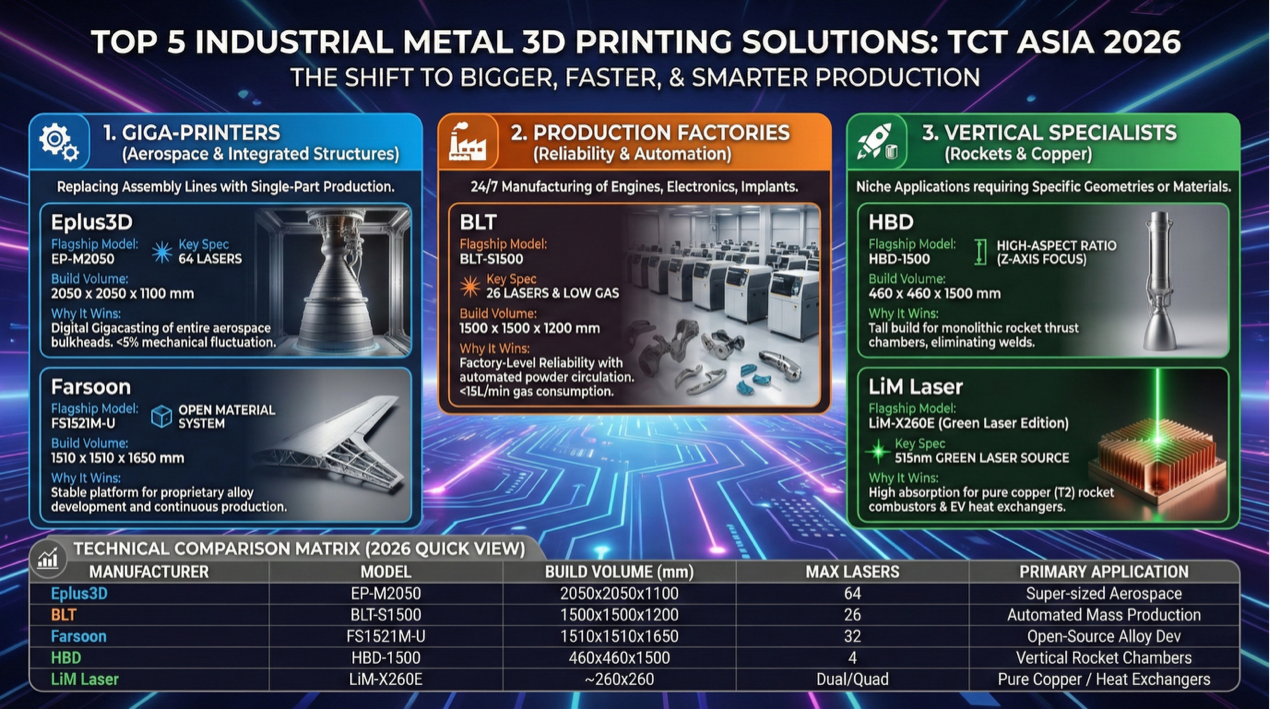

Market Data: Top 5 Industrial Metal 3D Printing Solutions at TCT Asia 2026

Source: DateTime:2026.02.04 Hits: 49

TL;DR

At TCT Asia 2026, metal additive manufacturing has officially entered the "Gigafactory Era". The focus is no longer just on printing metal, but on mass production efficiency and megascale structures.

- The Breakout: Eplus3D and Farsoon are shattering size limits with >2-meter build volumes and 64-laser arrays, aimed at replacing traditional casting.

- Vertical Specialization: HBD is redefining aerospace production with extra-tall Z-axis machines for rocket engines, while LiM Laser utilizes green lasers to master pure copper.

- Factory Automation: BLT is driving the standard for "lights-out" manufacturing with fully automated powder circulation and industrial-grade stability.

Event Essentials: TCT Asia 2026

At TCT Asia 2026, the metal AM trend is undeniable: printers are getting bigger, faster, and significantly smarter. Chinese OEMs have taken a definitive lead in the "Laser Wars," launching systems with build volumes and laser counts that were previously considered impossible.

This guide analyzes the Top 5 Metal AM Solutions defining the 2026 landscape, categorized by their specific industrial superpowers.

1. The "Giga-Printers" (Aerospace & Integrated Structures)

Target: Replacing assembly lines with single-part production.

Eplus3D: The Volume King

- Flagship Model: EP-M2050

- The Spec that Matters: 64 Lasers (Optional)

- Build Volume: 2050 x 2050 x 1100 mm (Customizable Z to 2000mm)

- Why it Wins: Eplus3D has broken the physical limits of MPBF (Metal Powder Bed Fusion). With a 64-laser array and a build volume exceeding 2 meters, this machine is designed for "Digital Gigacasting"—printing entire aerospace bulkheads or chassis in one go, with mechanical property fluctuation kept under 5%.

Farsoon: The Open Platform

- Flagship Model: FS1521M-U

- The Spec that Matters: Open Material System

- Build Volume: 1510 x 1510 x 1650 mm

- Why it Wins: Farsoon continues to champion "Open AM." The FS1521M-U is built for users who need to develop proprietary alloys. Its unique solution to smoke and powder management over such a large span makes it a stable workhorse for continuous production.

- Note: Look out for the FS621M Pro, featuring a rectangular build chamber optimized for long, slender automotive parts.

2. The Production Factories (Reliability & Automation)

Target: 24/7 manufacturing of engines, electronics, and medical implants.

BLT: The Smart Factory Standard

- Flagship Model: BLT-S1500

- The Spec that Matters: 26 Lasers & Low Gas Consumption

- Build Volume: 1500 x 1500 x 1200 mm

- Why it Wins: BLT focuses on "Factory-Level Reliability." The S1500 isn't just big; it's efficient. With an automated powder circulation system and gas consumption <15L/min, it drastically reduces operational costs (OPEX) for high-volume aerospace runs.

- For Consumer Electronics: The BLT-S400 remains the industry standard for mass-producing titanium hinges for foldable phones.

3. The Vertical Specialists (Rockets & Copper)

Target: Niche applications requiring specific geometries or materials.

HBD: The Rocket Engine Specialist

- Flagship Model: HBD-1500

- The Spec that Matters: High-Aspect Ratio (Z-Axis Focus)

- Build Volume: 460 x 460 x 1500 mm

- Why it Wins: While others go wide, HBD goes tall. The HBD-1500 is purpose-built for the commercial space industry, specifically for printing monolithic liquid rocket engine thrust chambers. Its vertical design eliminates the need for welding sections together.

LiM Laser: The Copper Master

- Flagship Model: LiM-X260E (Green Laser Edition)

- The Spec that Matters: 515nm Green Laser Source

- Why it Wins: Standard infrared lasers struggle with reflective metals like copper. LiM Laser's green laser technology boosts copper absorption to >40%, making it the go-to machine for printing pure copper (T2) rocket combustors and EV heat exchangers.

Technical Comparison Matrix (2026 Edition)

A side-by-side look at the heavyweights.

Manufacturer | Model | Build Volume (mm) | Max Lasers | Primary Application |

Eplus3D | EP-M2050 | 2050 x 2050 x 1100 | 64 | Super-sized Aerospace Structures |

BLT | BLT-S1500 | 1500 x 1500 x 1200 | 26 | Automated Mass Production |

Farsoon | FS1521M-U | 1510 x 1510 x 1650 | 32 | Open-Source Alloy Development |

HBD | HBD-1500 | 460 x 460 x 1500 | 4 | Vertical Rocket Thrust Chambers |

LiM Laser | LiM-X260E | ~260 x 260 | Dual/Quad | Pure Copper / Heat Exchangers |