Metal Additive Manufacturing (AM), commonly referred to as metal 3D printing, has evolved rapidly over the past decade, revolutionizing industries such as aerospace, automotive, and healthcare. By enabling the creation of complex geometries, reducing material waste, and fostering design freedom, AM is transforming traditional manufacturing processes. In this context, TCT Asia has emerged as a premier platform for showcasing the latest advancements in metal AM technologies, offering insights into innovations shaping the future of manufacturing in the Asia-Pacific region.

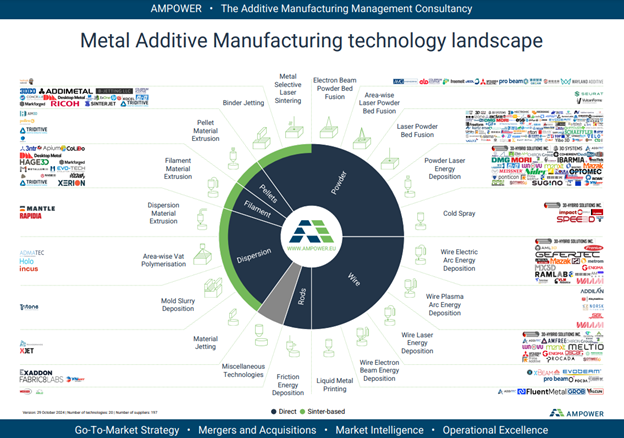

This article unpacks the AMPOWER Metal Additive Manufacturing Technology Landscape[1], highlighting 20 core technologies and exploring their relevance to industry trends and the upcoming TCT Asia 2025 event.

AMPOWER is a leading consultancy specializing in additive manufacturing. Its latest report maps 20 distinct metal additive manufacturing technologies and profiles 197 global suppliers. The report underscores the diversity of metal AM solutions, ranging from Powder Bed Fusion (PBF) to Directed Energy Deposition (DED) and Binder Jetting.

The infographic (as shown above) categorizes technologies based on the type of feedstock, including powders, wires, filaments, and dispersions, offering a comprehensive view of the current metal AM landscape.

Powder Bed Fusion stands out as one of the most widely adopted metal 3D printing technologies. It uses a laser or electron beam to selectively fuse powdered material layer by layer.

DED involves depositing material (either powder or wire) directly onto a substrate while simultaneously melting it with a focused energy source like a laser, electron beam, or plasma arc.

Binder Jetting 3D printing uses a liquid binding agent to selectively bond layers of metal powder, followed by a sintering process to consolidate the part.

Material extrusion, including filament and pellet extrusion, is commonly associated with plastic 3D printing but is increasingly applied in metal AM.

Several emerging technologies hold the potential to disrupt traditional manufacturing processes:

Diagram from AMPOWER

TCT Asia serves as a vital link between technological innovation and market application, offering a platform for businesses to explore cutting-edge metal additive manufacturing solutions. This event will again take place from March 17th to 19th, 2025, at the National Exhibition and Convention Center (NECC), Shanghai, in Halls 7.1 and 8.1. For companies attending the event, understanding these technologies' nuances is crucial for aligning their strategies with industry trends.

Key reasons why TCT Asia is significant:

As metal additive manufacturing matures, several trends are shaping its future:

The AMPOWER Metal Additive Manufacturing Technology Landscape offers a comprehensive view of the evolving AM ecosystem, highlighting the diversity of technologies and their industrial relevance. For businesses looking to stay ahead of the curve, attending TCT Asia 2025 is a strategic move. The event provides a unique opportunity to engage with industry leaders, explore innovative technologies, and shape the future of manufacturing.

Join TCT Asia 2025 to experience the latest in metal additive manufacturing, discover collaboration opportunities, and gain actionable insights to drive your business forward. Don’t miss this chance to be part of the AM revolution.

[1] Metal Additive Manufacturing: Technology overview. Available at:

https://ampower.eu/infographics/metal-additive-manufacturing/ (Accessed: December 13, 2024)