Selective Laser Melting (SLM), also known as SLM 3D printing, is changing how parts are manufactured. It uses a high-power laser to fuse metal powder particles together, layer by layer, to form a solid, three-dimensional object. This method can make complicated shapes, use less material, and speed up making things. It’s a key part of the future of making products. The TCT Asia 2025 exhibition, a big event in Shanghai about 3D printing and additive manufacturing, will highlight SLM technology.

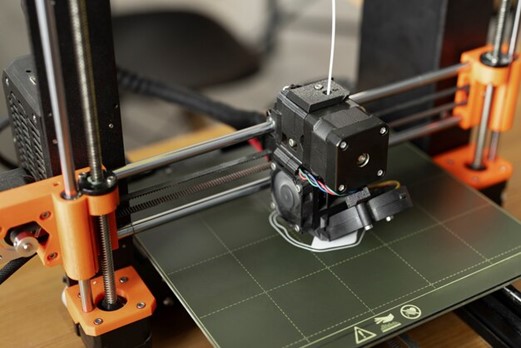

SLM technology uses a powerful laser to layer by layer melt and fuse metal powders, creating detailed parts from digital designs. This process starts by spreading metal powder on a build platform, which the laser melts to form a layer. The platform then lowers, and more powder is added, with the laser repeating this step until the part is complete. This method ensures high accuracy and allows for the creation of complex parts that are hard to make with traditional methods.

SLM 3D printing offers numerous advantages. It streamlines production by making intricate designs with fewer tools, which saves time and money and reduces material waste through the reuse of leftover powder. This technology is used across different industries, such as aerospace, medical, and automotive. For example, it can create lighter, stronger turbine blades for improved aircraft fuel efficiency, custom implants and prosthetics in healthcare, and high-quality engine and transmission components in automotive.

The growth of SLM technology is happening fast worldwide, with big improvements in research and use. China is moving towards refinement and professionalism in SLM printing, thanks to government support for smarter and better manufacturing. This technology is being used in many industries to make manufacturing more efficient and varied. Researchers are working hard to make SLM parts better by improving laser accuracy, using better metal powders, and creating software for better control.

Outside of China, the SLM 3D printing market is also growing, with more money being put into research to solve problems like finding good materials and making SLM machines cheaper. There’s also a trend towards making machines that mix SLM with other methods, making it easier to handle complicated manufacturing jobs.

TCT Asia, a top event for additive manufacturing and 3D printing, is important for showing new SLM technology and encouraging its use in different fields. It’s the biggest of its kind in Asia and draws experts, researchers, and tech lovers from worldwide, offering a great place for sharing knowledge and finding new business chances.

The TCT Asia 2025 will showcase the latest in additive manufacturing, including SLM technology. Visitors will see new SLM printers, materials, and software, pushing the limits of what’s possible in making things. The event will also cover market trends and new uses, giving insights into SLM’s future. With fast innovation, it’ll help launch new products and encourage teamwork for tech advancement.

SLM technology has many benefits but faces challenges that need to be solved for wider use. One big problem is the limited range of materials that can be used, which limits its use in some areas. There’s a need for research to find new materials that can meet different needs. Also, improving how parts look and feel after printing is important.

Another issue is that SLM machines are expensive, making it hard for small businesses to afford them. Making the machines cheaper, faster, and more reliable is key to making SLM more available. However, SLM 3D printing has great potential. Its accuracy and ability to manufacture complex parts make it perfect for industries that need custom solutions, like aerospace and healthcare. Also, SLM’s use of materials aligns well with the push for sustainable manufacturing, making it a strong choice in a world that values resources.

The combination of SLM technology and the TCT Asia 2025 event is a key moment for the manufacturing industry. SLM 3D printing is changing manufacturing by combining innovation, precision, and sustainability. The TCT Asia 2025 will help speed up SLM’s adoption by showcasing new developments and encouraging industry partnerships. Looking forward, SLM technology is expected to become even more important in manufacturing. Future advancements will likely increase its benefits, making production more efficient, sustainable, and versatile and changing the face of modern industry.