The automotive industry is on the cusp of a significant transformation, with 3D printing technology at the forefront of this change. As the industry continues to evolve, the integration of 3D printing in automotive design and manufacturing is becoming increasingly prevalent. This technology is not only reshaping the way vehicles are conceptualized and produced but is also redefining the standards of efficiency, innovation, and customization.

The TCT Asia 2024, to be held in Shanghai from May 7-9, is a testament to 3D printing's growing role in the automotive sector. It is supposed to provide a platform for industry leaders to showcase their advancements and discuss the future of manufacturing.

Overview of the Application of 3D Printing Technology in the Automotive Industry

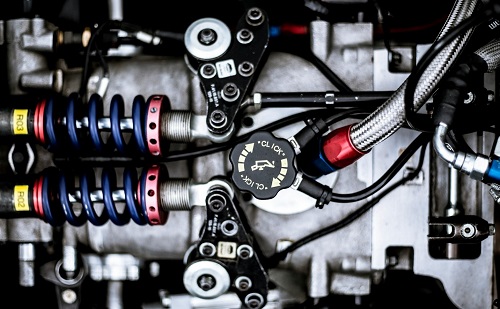

Automotive 3D printing has opened new avenues for innovation in automotive design. The technology enables designers to create intricate and lightweight components that were once impossible to manufacture using conventional methods. This has led to significant improvements in vehicle performance, fuel efficiency, and overall weight reduction. For example, automotive giants like BMW and Audi have embraced 3D printing to produce complex parts and prototypes, which have resulted in faster development cycles and reduced production costs.[2][3]

Furthermore, 3D printing has revolutionized the manufacturing of end-use parts. Companies are now able to produce components with optimized lattice structures, which provide the necessary strength while reducing material usage. This has been particularly beneficial in the production of lightweight vehicles, which are essential in meeting the increasing environmental and fuel efficiency standards.

Advantages of 3D Printing in Automobile Manufacturing

The benefits of 3D printing in the automotive industry are manifold. One of the most notable advantages is the enhancement of production efficiency. By eliminating the need for traditional tooling and molds, 3D printing streamlines the manufacturing process, leading to reduced lead times and costs. This is especially crucial in the early stages of product development, where rapid prototyping is essential to test and refine designs.

Additionally, 3D printing enables mass customization. As consumer demand for personalized vehicles grows, manufacturers can leverage 3D printing to produce unique parts and components tailored to individual preferences. This not only enhances customer satisfaction but also opens up new revenue streams for automotive companies.

Challenges Faced and Industry Prospects

Despite the numerous advantages, the adoption of 3D printing in the automotive industry is not without challenges. Material limitations and high costs remain significant barriers. The development of new materials that can withstand the rigors of automotive applications is an ongoing area of research and development. However, with continuous advancements in material science, it is expected that these challenges will be overcome, leading to wider adoption of 3D printing in the industry.

The economic downturn has also affected the industry, with some companies facing financial constraints. Yet, the resilience of the sector is evident, as demonstrated by the successful financing rounds of companies like Farsoon. This indicates a strong belief in the long-term potential of automotive 3D printing and its ability to drive growth and innovation in the industry.[4]

Conclusion

The integration of 3D printing in the automotive industry represents a paradigm shift in manufacturing. It offers a multitude of benefits, including enhanced design capabilities, improved production efficiency, and the ability to meet the growing demand for customization. While challenges such as material limitations and economic factors persist, the industry's commitment to innovation and technological advancement is unwavering.

As the technology continues to mature, it is poised to play an even more significant role in the industry, driving sustainable growth and setting new standards for excellence in automotive design and manufacturing. For more industry updates and TCT Asia 2024 event information, please explore our official website and Facebook page.

Foot Notes

1. Mordor Intelligence. (n.d.). 3D Printing in Automotive Industry - Trends, Size & Share. Retrieved from https://www.mordorintelligence.com/industry-reports/automotive-3d-printing-market

2. Audi MediaCenter. (n.d.). Audi Demonstrating 3D Printing Expertise with In-House Design Software in Neckarsulm. Retrieved from https://www.audi-mediacenter.com/en/press-releases/audi-demonstrating-3d-printing-expertise-with-in-house-design-software-in-neckarsulm-12587

3. 3D Printing Industry. (n.d.). BMW opens new €15 million additive manufacturing campus in Munich to “industrialize 3D printing”. Retrieved from https://3dprintingindustry.com/news/bmw-opens-new-e15-million-additive-manufacturing-campus-in-munich-to-industrialize-3d-printing-173039/

Tencent News. (2024, January 25). Farsoon. Retrieved from https://new.qq.com/rain/a/20240125A05AM400