BMF Precision, which is the only company in the world that can make 3D printing precision accurate to 2 microns, with both ultra-high tolerance control capability and industrialized application, is also one of the few companies that export precision machining equipments to major application markets around the world. Continuous product development capability has always been the focus of attention in the industry.

Recently, TCT Asia Perspectives team went to BMF Precision Shenzhen to chat with Mr. Zhou Jianlin, Vice President of BMF Precision, from the company's choice to enter into the micro-nano 3D printing, reviewing the 8-year development history. He analyzed the competition situation of domestic and international 3D printing market with a calm and restrained vision. Adhering to the original intention, BMF Precision has been making continuous efforts in product development and application expansion. In May this year, they will unveil a new generation of 3D printing masterpieces at TCT Asia.

The following content is compiled from the interview transcript

Vice President of BOSTON MICRO FABRICATION

Mr. Zhou Jianlin

In the booming development of metal 3D printing technology at home and abroad, everyone is curious why BMF Precision chooses the "small but fine" track of micro-nano 3D printing technology in the environment where most people choose to do "large size"? What is the basis and background for choosing this track?

This is a very good

question. We have been attending TCT exhibitions around the world for a long

time, including TCT Asia, TCT 3Sixty in the UK, Rapid+TCT in the US, and TCT

Japan, so we have been keeping an eye on the development of the 3D printing

industry as a whole.

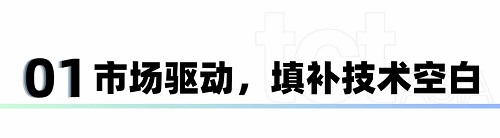

RAPID+TCT 2023 on site

You mentioned the metal piece, it is true that in recent years in the global

development are relatively fast, especially in the large aerospace this field

to do more and more business, of course, is a very good trend. However,

additive manufacturing is a platform technology and also belongs to the

category of material processing, so metal is only one of the pieces of material

processing. We have been focusing on the

processing of resin and ceramic materials, and our core competence is precision

manufacturing and precision processing.

Live from TCT 3Sixty 2023

Micro and nano 3D printing is a sub-segment of the large 3D printing industry, which is mainly used to solve the processing and manufacturing problems of precision small products and complex devices that are difficult to be handled by any traditional technology. So, what are the market demand and development trend? And what do we do? This is driven by the market.

At present, it seems that, whether in electronics, communications, or medical, industrial development is very fast, especially some of our more familiar consumer products, such as cell phones, the thinner, the lighter, and folding function, and so on. Then some components inside these designs in the case of complex structure, must be made especially lightweight to meet the needs. As well as some wearable products, such as TWS headphones, relative to the previous headset and in-ear, now wireless Bluetooth design is very intelligent. It can be seen that both the size of the micro-nano details and complex configuration of precision devices, all over the industrial production and all aspects of people's lives, of course, also appeared in a large number of "high-precision", foreign manufacturing technology monopoly in the field.

*RJ connectors with a minimum wall thickness of 140 μm, a minimum pitch of

280 μm, and an overall structure that can be molded in a single print run of at

least 50 units.

In contrast, traditional manufacturing methods in the face of ever-changing technological advances, often bottlenecks significant. The market has always existed, but in the past, why many downstream manufacturers would choose the more expensive, or more inconvenient to do some of the traditional way, because our printing technology it can not meet this requirement. Then, BMF Precision through the development of these seven or eight years, technology continues to mature, has done a lot of application cases in these applications, which further strengthened our confidence, find a better position, determined to continue to go deeper in this industry.

How did we become a global leader in

ultra-high-precision 3D printing?

首先还是前面提到的市场驱动。公司成立初期,正值 3D 打印技术在全球范围内逐渐兴起。就我们中国企业而言,有很多在产品方面做得很好,但真正能够将基础设备出口到海外的还是比较少的。尤其过去这些年,中国在很多产业中、在核心高端设备上更是受到限制。在这样的背景和使命下,摩方精密在设备制造方面,稳操基本盘,在25μm、10μm、2μm微纳3D打印机都有主打的设备,且在科研及工业领域有着非常扎实的客户基础。First of all, we are still driven by the market as mentioned earlier. At the beginning of the company's establishment, 3D printing technology was emerging globally. As far as we Chinese companies are concerned, there are many that are doing well in terms of products, but there are few that are really able to export basic equipment overseas. Especially in the past years, China has been limited in many industries and in the core high-end equipment. In such a background and mission, BMF Precision in the equipment manufacturing, steady control of the basic plate, in 25μm, 10μm, 2μm micro-nano 3D printer have the main equipment, and in the scientific research and industrial field has a very solid customer base.

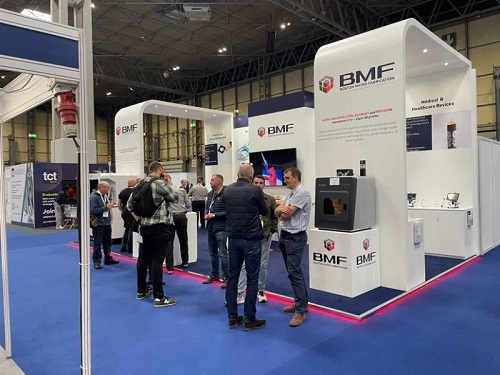

microArch S230(2μm)

Secondly, original technology drive. In the 8 years of development, BMF Precision has continuously made technological breakthroughs and innovations. In 2021, microArch S240 won the Prism Award, the highest award in the field of global optoelectronic science and technology in 2021, which is the first time for a Chinese enterprise to win this award for its leadership in local original precision manufacturing technology. Furthermore, we continue to explore innovative applications, empower and incubate products in related application fields, and make efforts to open up the layout of terminal application products. At present, "Extremely Thin and Strong Dental Veneer" is one of the breakthrough application products brought by BMF Precision utilizing subversive technology, which is a brand-new application in the field of biomedical treatment. Relying on the core technology accumulated over a long period of time, BMF Precision's 3D printing technology has been widely used in a number of vertical fields, such as medical devices, precision connectors, etc., and has established cooperative relationships with a number of well-known enterprises.

What is the current layout of BMF Precision in

China/Asia-Pacific region? What kind of "map" does it plan to present

in the future? How to do it?

Our own positioning

is to be a global market enterprise, so in addition to the Asia-Pacific region,

our other big market is in Europe and the United States. Because the entire 3D

printing market is still distributed in Europe and North America, as well as

the Asian region is more concentrated in East Asia, and China is indeed a major

market, so in addition to Australia, Singapore, etc., our layout in China is

relatively deep.

Our head office is in Chongqing, the last two years the development of faster,

has been in Xiamen, Beijing, Shenzhen, Wuhan, Nanjing, Xi'an, Hangzhou and

other places to set up offices, but also in Japan, the United States and other

places to set up an overseas branch, to further accelerate the global market

expansion and sustained growth in the future.

In the short term, we firstly ensure to steadily push forward the equipment sales and further strengthen the follow-up customer tracking after-sales and technical support. The new equipment to be released in TCT in May this year, which is also the R&D masterpiece of BMF Precision in these years, will provide customers with more efficient, smarter and friendlier using experience.

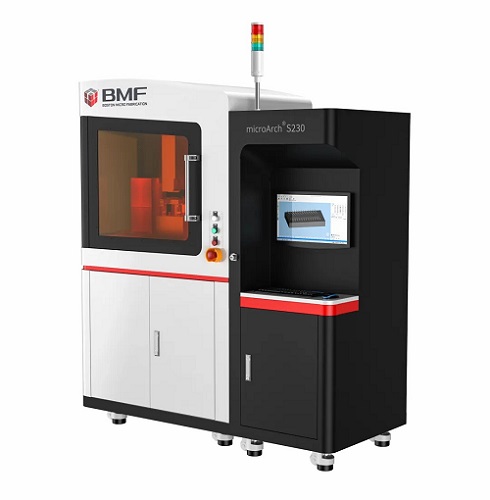

Secondly, we continue to step up the research and development of innovative technologies to expand end-use applications. Taking dental veneers as an example, when the surface of the teeth is defective, stained and other diseases, the use of ceramic restoration materials "sticking" on the surface can restore the shape and improve the color. At present, the minimum thickness of zirconia dental veneers based on machining in the world is more than 300μm. However, the thickness of the veneers we have created in cooperation with the North University Dental Hospital has been significantly reduced to 40μm, minimizing the need for patients to grind their teeth and preserving tooth enamel.

In the direction of long-term layout, BMF Precision will be committed to establishing a more complete global market network and accelerating the strategic layout of R&D, innovation, exhibition center and sales as a whole. We hope to allow BMF to enter more fields, at the same time, we will go in the terminal, product side and upstream and downstream customers to cooperate with each other, BMF's materials and equipment further into the terminal products, and ultimately transition to become a technology-enabling platform company.

Through various channels of news that BMF Precision

will officially release the Dual series equipment at the TCT site, for the

first time to realize the composite precision in the same layer and different

layers of free switching, also please talk about the BMF this time in the new

technology and series of new products of the breakthroughs?

Our company has been focusing on precision production or micro-nano production, so we have always attached great importance to R&D and technological innovation. Over the years, we have been continuously launching new products, including 2μm precision, 10μm precision, and 25μm precision, to fill some technical gaps and meet the market needs.

The Dual series devices you just mentioned are equipped with BMF's new technology - Complex Precision Light Curing 3D Printing Technology. This device is mainly aimed at the demand for fine processing of complex structural parts in industrial manufacturing. By combining different printing precision, it breaks through the inherent contradiction between large-size and high-precision, and perfectly combines large-format and very small feature sizes, which effectively solves the problem of difficulty in combining large-size and high-precision in traditional printing.

We are very much looking forward to this world's first dual-precision printing device. So, can Mr. Zhou tell us about the scenarios in which this device will appear in the future? What application areas can it solve?

There are a lot of application scenarios, and we all have a common demand: to meet the dual needs of high precision and high efficiency at the same time. 10 years ago, I already received a customer's demand in this regard, and he hoped that the equipment would improve the speed and efficiency of the machine while hitting well, so that it could reduce the cost and at the same time satisfy the demand for faster iteration of the product.

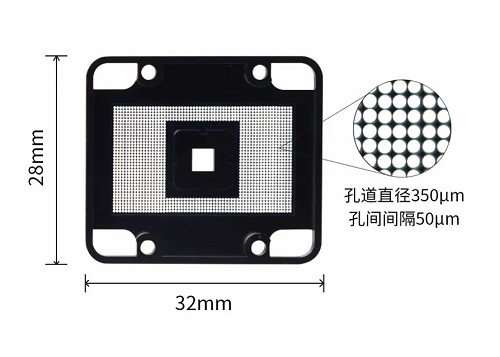

Then, for example, in the field of precision electronics, this equipment can print chip connectors, connectors, sensors and other complex precision structures, for small batch, scale manufacturing of precision instruments, fully meet the manufacturers of precision and complex connectors and other parts of the mass production needs, can greatly enhance production efficiency. For example, the AI chip, it is used above some packaged backplane or connector. An AI CPU to play a lot of chips, the area of the backplane is fixed, but its surface is covered with thousands of small holes, the required precision requirements are very high, then the need for 2μm precision to do, but the other parts of the precision requirements are relatively not so high, may be 10 μm or 25 μm can meet.

As well as in the field

of precision medicine, its

advantages in the manufacture of complex structures, personalization, material

diversity, rapid prototyping and iteration, etc., provide strong technical

support and new possibilities for the development of the field of high-end

medical devices and biomanufacturing technology.

Finally, in the field of scientific

research such as mechanics, bionics, micro-mechanics, microfluidics,

metamaterials, new materials, biomedical and terahertz, etc., the ability to

manufacture complex microstructures is of great significance to materials science

research and new device development, helping universities and research

institutions to step up the transformation of scientific and technological

achievements, further empowering the industry, industry-academia linkage,

providing stronger scientific and technological support for social and economic

development, and promoting China's Manufacturing industry towards the middle

and high end of the global value chain.

This case is very much, the emergence of this technology can change the thinking of some designers, who used to dare to think but can not do, so now you can "dare to think and dare to do". When I receive positive feedback from our customers, who evaluate us as "soul engineers", I feel that it is a great sense of achievement for us to devote ourselves to this industry.

In terms of light-curing 3D printing, how do you see other domestic and international competitors?

Yes, the technology

we use is light curing, so we have been following the development of light

curing in this industry. Then, light curing has both high precision and low

precision, as well as resin printing, ceramic printing, and so on, all of which

are peers. That the domestic and foreign competitive environment is also

different, foreign manufacturers pay more attention to do some basic

innovation, original innovation things, showing a differentiated competitive

pattern, benign development. Domestically, I have a feeling that the opposite

is true with foreign countries, everyone's point of contention is in marketing,

copywriting beautification, etc., which is not a challenge to our competition

in the country, but this will cause a certain degree of end-users will be

misleading, interfere with the segmentation of the technology to make a true

and accurate judgment.

In recent years,

China's additive manufacturing industry has been developing rapidly, and a

number of well-known additive manufacturing enterprises have emerged, and we

are all rivals, but also comrades in arms. As a processing manufacturer, BMF

Precision has always kept a sense of reverence, learning from customers in the

downstream field with an open mind and growing together.

What are the challenges facing BMF Precision? What is the future direction

of product and technology development?

In this industry, I

think there are always challenges. First, 3D printing technology is, after all,

a material processing technology, how to promote the technology to find the

right application, how to land, are required to spend a long time to

accumulate, optimize, in order to present a final product that everyone is

satisfied.

The second point, we know that customers want a comprehensive solution, not by selling a piece of equipment can be solved. This brings us back to what I said earlier, that the company needs to continuously cultivate its internal strength and overcome the difficulties in the process together with the customer in order to truly meet the client's needs.

If we have been stuck

in the prototype manufacturing, just sell equipment, then the ceiling of the

industry is there, there is no way to truly solve the problem of industry

applications, which results in the limitations of the market space. Then

investors or practitioners, will have to leave the industry, not to mention the

possibility of more in the future.

Thank you, Mr. Zhou, for sharing your insights. So in May, TCT Asia will

be held in Shanghai, Mr. Zhou has what to expect?

Let me start with my

feelings, I think TCT is a very good exhibition platform, including both

foreign and Asian exhibitions. We have a lot of expectations for TCT Asia, one

of which is that we hope TCT Asia will be more internationalized.

With the development of the domestic additive industry, the proportion of domestic manufacturers on the site is also growing, TCT as a bridge and a window, we also hope that more overseas exhibitors can participate in, but also including the conference forum, the future to invite more domestic and foreign experts, practitioners, application users to participate in, mutual exchange, understand each other's development, and open up horizons.

Join us at TCT Asia, connect with industry innovators as you explore the entire AM ecosystem including design, materials, hardware, software, post-processing, and quality. 10,000+ professionals will unite to hear about the latest trends, explore the latest immersive AM technologies and find solutions to their AM challenges.

TCT ASIA 2024

Tuesday 7th May 09:00 - 17:30

Wednesday 8th May 09:00 - 17:30

Thursday 9th May 09:00 - 15:00

NECC(Shanghai)7.1&8.1H