CN/EN

CN/EN

CN/EN

CN/EN

Additive Manufacturing (AM) has emerged as a

pivotal domain in the progression of industrial technology, offering innovative

solutions for complex component manufacturing. However, traditional metal 3D printing methods

have been hindered by the need for support structures, which can complicate the

production process and add to the overall cost. This has led to the exploration

and development of minimal support or support-free alternatives that promise to

revolutionize the industry.

Principles and Characteristics of No

Support Metal 3D Printing

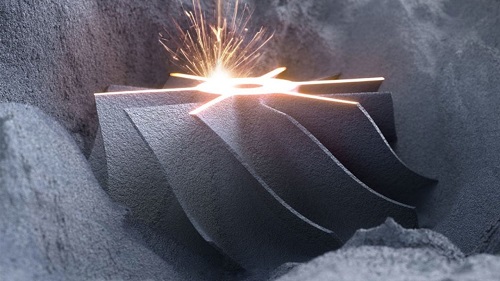

Laser Powder Bed Fusion (LPBF) is a key

technology in the field of minimal support metal 3D printing. It involves the

use of a laser to selectively melt and fuse metal powders layer by layer,

building up a part from the ground up. The absence of support structures in

this process is a significant advantage, as it eliminates the need for

additional steps to remove these supports, reduces material waste, and simplifies

the post-processing phase. According to a study published in Science,

the presence of powder in the LPBF process can lead to variations in the

porosity boundary, which is sharp and smooth in the power-speed (P-V) space,

indicating the potential for high precision and control in the printing process.[1]

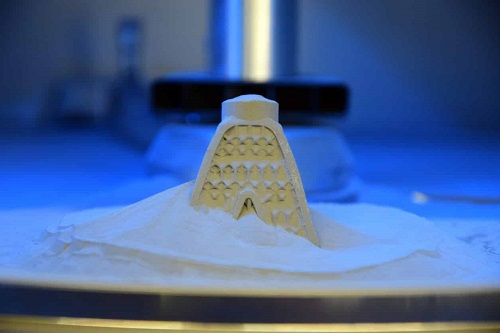

The features that distinguish minimal

support metal 3D printing include the ability to produce intricate geometries

that would be impossible or highly challenging with conventional manufacturing

methods. This is due to the precision with which the laser can melt the powder,

allowing for high-resolution and detailed part production. Furthermore, the

surface quality of the final product is often enhanced, as the absence of

supports reduces the need for extensive finishing work.

Innovative Achievements and Future Trends

The advancements in materials, equipment,

and processes have been remarkable. Researchers and engineers have expanded the

range of metals suitable for LPBF from titanium and aluminum to more exotic

alloys with unique properties. The equipment has also seen significant

improvements in terms of precision, speed, and reliability. For example, the

Fraunhofer Institute for Production Technology (IPT) has been working on

optimizing the LPBF process chain and integrating it into hybrid production

processes, which can lead to significant improvements in production efficiency

and cost-effectiveness. [2]

Looking ahead, one of the most exciting

trends is the intelligent integration of LPBF into hybrid production processes.

This involves combining additive manufacturing with traditional subtractive and

formative processes to optimize production efficiency and cost-effectiveness.

For instance, semi-finished products can be pre-machined or cast and then additively

enhanced using LPBF to achieve complex geometries that would otherwise be

unattainable.

Another promising area is multi-material

printing, which allows for the fabrication of components with varying material

properties within a single build. This can lead to parts that are not only

lighter but also stronger and more functional, catering to the demands of

industries such as aerospace, automotive, and medical. The development of

multi-material printing is particularly relevant for these industries, where

components often need to fulfill multiple functions and withstand diverse

environmental conditions.[3]

Get Ready to

Know More at TCT Asia 2024

The TCT Asia 2024 will be held from May 7th to 9th at the National Convention and

Exhibition Center (Shanghai) Hall 7.1 & 8.1. As the leading exhibition in

Asia's additive manufacturing industry, TCT Asia 2024 will showcase the latest

3D printing technologies and applications, including material technology,

supporting equipment, digital modeling, and 3D printing services.

During

the exhibition, visitors will have the opportunity to experience first-hand the

innovative achievements of leading companies such as Farsoon Hi-Tech, such as

the 16-laser and metal additive manufacturing system FS1521M for mass

production of oversized parts. To ensure a smooth visit, please make a

real-name reservation through the official website in advance to enjoy the free

ticket discount. For more details, please follow our Facebook page.

Conclusion

The advancements in minimal support metal 3D

printing, particularly LPBF technology, have opened up new horizons for

manufacturing. The elimination of support structures, the ability to produce

complex geometries with high precision, and the potential for intelligent

integration and multi-material printing make this technology a promising avenue

for future industrial applications.

As we look forward to TCT 2024 and beyond,

it is clear that minimal support for metal 3D printing will continue to play a

crucial role in shaping the future of manufacturing, enabling the production of

components that push the boundaries of design and functionality.

Footnotes

[1] Zhao, C., Rollett, A. D., & Sun, T.

(2020). Critical instability at moving keyhole tips generates porosity in laser

melting. Science, 370(6520), 1080-1084. Link

to the paper

[2] Fraunhofer Institute for Production

Technology (IPT). (n.d.). Homepage. Link to the IPT website

Join us at TCT Asia, connect with industry innovators as you explore the entire AM ecosystem including design, materials, hardware, software, post-processing, and quality. 10,000+ professionals will unite to hear about the latest trends, explore the latest immersive AM technologies and find solutions to their AM challenges. Make sure you are there too.

TCT ASIA 2024

Tuesday 7th May 09:00 - 17:30

Wednesday 8th May 09:00 - 17:30

Thursday 9th May 09:00 - 15:00

NECC(Shanghai)7.1&8.1H