At Paris Fashion Week, a set of 3D printed shoes from luxury fashion brand Dior have been showcased as part of the Dior Winter 23 by Kim Jones show.

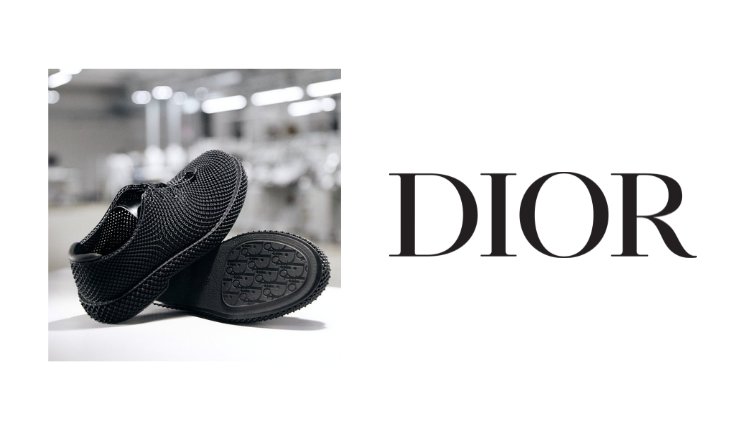

The two different types of shoes created by Dior, derbys and boots, were printed using laser powder bed fusion technology, but the brand did not disclose the specific system used. The footwear was just about visible on the catwalk beneath long pants that models were wearing, but close-up images have now been released.

In a video shared by the official Dior Twitter account, a member of the design team spoke about the sustainability of the shoes: “What interested us here is that, once the tongue has been unstitched and the undersoles and laces have been removed, 80% of the material can be entirely reused for other purposes. It’s a circular approach.”

According to Dior, the shoes are ‘pushing the limits of innovation’ and are a modern take on the traditional ‘Carlo’ designs from the company, with a model of the Carlo being scanned and digitised before selecting a texture.

The spiky texture used for the products was selected due to its ‘punk’ feel, according to the video posted to Dior’s Twitter.

The brand has used 3D printing in the past. It showcased the past and present of Dior through nearly 1,500 3D printed items in the Dior gallery, as well as a pop-up store created by 3D printing company WASP using eco-friendly materials.

More recently, Dior developed the Dior AI Skin Analyser, a tool that will be used to give customers skincare product recommendations that will be more suited to their needs.

Adidas has been offering shoes with 3D printed midsoles for a number of years, using technology from Carbon. In August 2022, Adidas unveiled the new 4DFWD running shoe with additively manufactured lattices.