Powder handling equipment manufacturer Volkmann GmbH is to offer a new line of closed-loop and stand-alone, automated metal powder management systems specifically designed for integration with EOS metal additive manufacturing (AM) systems.

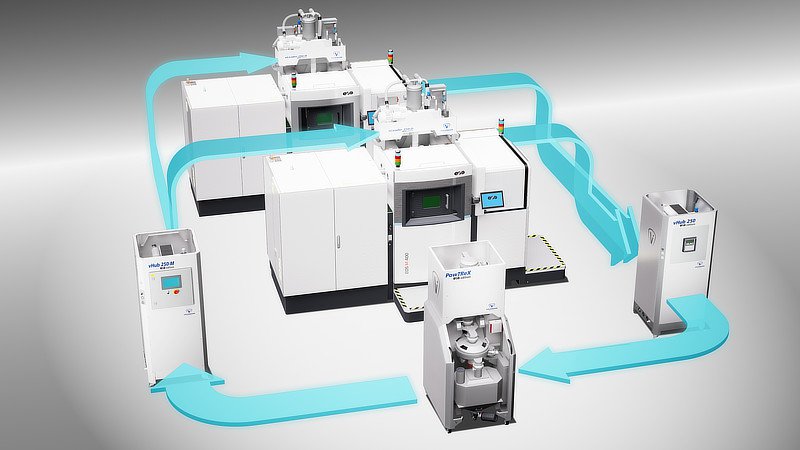

The partnership with the industrial 3D printer manufacturer will see EOS Edition powder handling systems offered for its EOS M 400 series machines. The central metal powder management systems can be used to automatically control the transfer and loading of material from storage into 3D printers, for capturing and sieving of excess powder for reprocessing, and automated vacuum drying of powders. Buffer storage units and other accessories are also available with the new systems. The EOS Edition can operate unattended, 24/7 as a fully enclosed, sealed circuit to eliminate metallic dust from the workplace, protect workers from potential exposure, and protect metal powders from ambient moisture and contamination.

“Our new systems provide EOS end-users with a complete, plug-and-play, automated powder handling solution that can scale as their production needs increase,” says Christian Mittman, director of advanced solutions for Volkmann. “This is a logical next step in our close relationship with EOS, and one that we feel will benefit EOS customers with faster, safer, more reliable printing and consistently high quality printed parts.”

Back in October, EOS announced its new EOS M 300-4 1kW 3D printer, due to be commercially available in February, will be offered alongside the Volkmann PowTrex EOS Edition powder handling system to ‘further optimise’ its workflow.