Australia has successfully launched its first scientific satellite in over two decades with the help of additive manufacturing.

With support from the Australian Space Agency, the SpIRIT (Space Industry Responsive Intelligent Thermal) nanosatellite is operated by the University of Melbourne, and was built in collaboration with the Italian Space Agency, and several Australian SMEs, including metal 3D printing company Titomic.

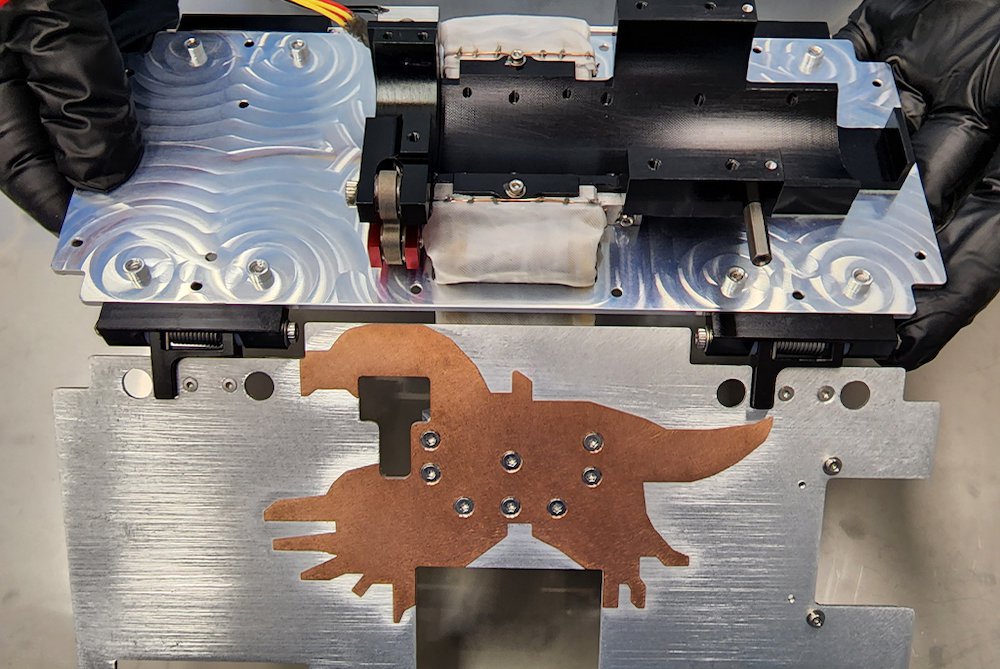

The Melbourne-based company’s cold spray additive manufacturing technology was used to develop the satellite’s thermal management system. The satellite features a thermal bi-metallic radiator design, which was cold-sprayed in pure copper using Titomic’s TKF 1000 system, and coated with mirror tape on one side. This design maximises thermal efficiency, enabling the satellite to host heat-sensitive instruments that are typically reserved for larger satellites. Titomic said the radiator’s unique ‘bird-shaped’ spray pattern allows the satellite to efficiently reject heat, enhancing its thermal performance ratio.

Herbert Koeck, Managing Director of Titomic described the satellite’s high-efficiency radiator panels as “crucial” to its operation.

This latest development builds on the adoption of Titomic's technology by other aerospace and space companies such as Airbus, Gilmour Space, and Ascent Aerospace.

Koeck said: “SpIRIT’s journey into space is not just a technological triumph. It’s also a significant step in scientific discovery.”

SpIRIT launched on December 2nd from Vandenberg Space Force Base in California, USA, on board the SpaceX Falcon 9 rocket. The satellite has been equipped with solar panels, thermal radiators, cameras, guidance systems, an electric propulsion thruster, and computers, as part of a two-year mission to observe X-ray and gamma-ray emissions from space. SpIRIT will operate with the High Energy Rapid Modular Ensemble of Satellites (HERMES). Once the mission is concluded, SpIRIT will return to Earth and burn up on re-entry.

3D printing for space exploration is a growing sector. Last week, Ursa Major announced it had raised 138 million USD in its Series D and D-1 funding rounds to support its 3D printed rocket propulsion technology. Earlier this year, printers from Chinese metal AM company Bright Laser Technologies were used to produce rocket components in the recent Landspace Zhuque-2 (ZQ-2 Y2) launch mission, and in November, Ariane Group began working with Oerlikon to 3D print a set of heat management components for its new Ariane 6 rocket launcher. This year also saw a major milestone from Relativity Space, which launched its Terran 1 rocket - the first rocket to be mostly made with additive manufacturing and successfully launched - though the two-stage launch vehicle failed to reach orbit.