General Motors has acquired casting manufacturer Tooling & Equipment International (TEI), a long-term user of Voxeljet’s binder jetting technology and supplier to Tesla.

International news agency Reuters broke the news last week and has reported that the acquisition is a key element in General Motors’ strategy to ‘make up ground on Tesla’. Tesla is said to have leaned on TEI, as well as three other suppliers, to facilitate its Gigacasting processes for the casting of large car structures in one piece.

By integrating TEI into General Motors, the automotive giant told Reuters it was ‘bolstering its portfolio of innovations and secure access to unique casting technology.’ TEI has reportedly been working with Tesla since 2017, with the casting company then agreeing a three-year contract with Voxeljet for the purchase of 3D printed sand moulds and cores in February 2018. While working with Tesla, TEI is believed to have supported the development of Tesla’s Model Y, Model 3, Cybertruck and heavy-duty Semi truck by prototyping large moulds.

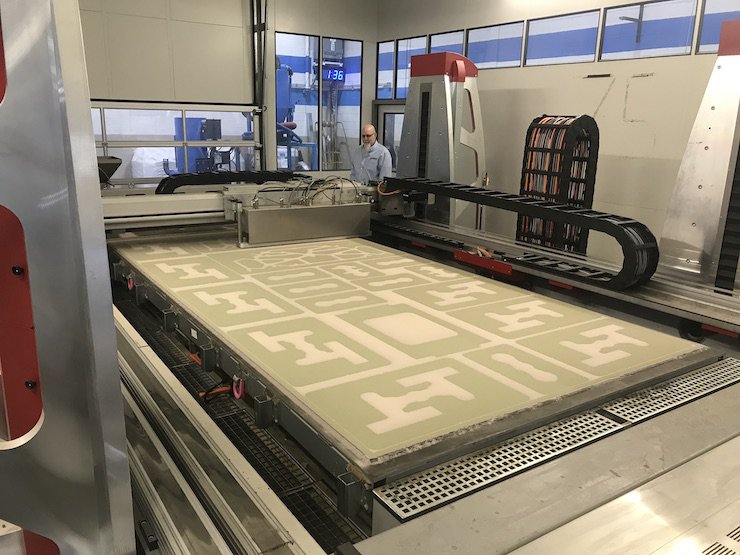

Come 2021, TEI was using two VX4000 sand 3D printing systems from Voxeljet and soon would earn itself a reputation as one of the largest users of sand 3D printing in the United States. Earlier this year, it was revealed the company had purchased a third VX4000 machine – expanding its additive manufacturing capacity to up to 2.5 litres per year – and was working with General Motors, producing cast cores for the series production of large-format, weight-saving structural components for the electric Cadillac CELESTIQ vehicle.

With its expanded sand 3D printing capacity, TEI has been able to print hundreds of cores for several vehicle sets in one night. It is this capability that initially attracted General Motors to partner with the company and subsequently acquire it. It is understood that TEI will remain its own business with General Motors operating as its parent company.