AddUp has announced that it has joined the Dassault Systèmes 3DEXPERIENCE platform ecosystem. With this platform, Dassault Systèmes offers a dedicated set of applications for 3D printing, including new material characterisation, adapted design and build job preparation and simulation, shopfloor scheduling and execution monitoring.

Dassault says that by working on a single platform, users can ensure digital continuity across the entire lifecycle of parts produce.

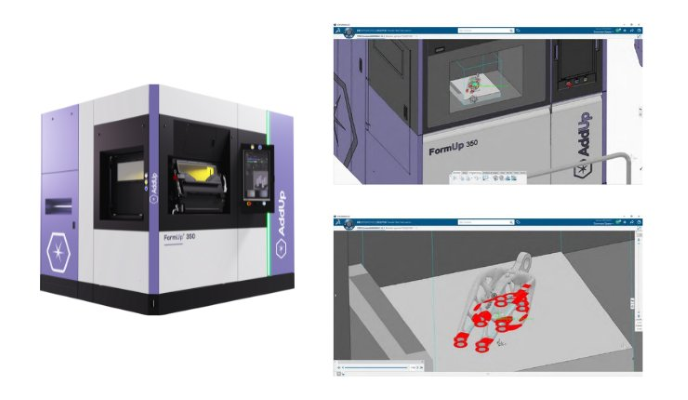

The companies created a ‘Virtual Twin’ of AddUp’s FormUp 350, using AddUp NTwin, a solution dedicated to FormUp interporability. AddUp says the virtual twin enables 3DEXPERIENCE platform users to seamlessly produce a job file, retrieve additional build information and run simulations. The virtual twin is available to users of the platform in the AddUp community hosted by Dassault Systèmes.

“Dassault Systèmes and AddUp have developed a virtual twin of the FormUp 350 machine in the 3DEXPERIENCE platform which enables the production file to be created interactively. Thanks to this virtual twin, Dassault Aviation is able to ensure digital continuity from design to manufacturing of the part in the 3DEXPERIENCE platform,” said Sylvain Belz, 3D Metal Printing Manager for Dassault Aviation.

AddUp says that through leaving the standard asynchronous workflow and its CAD to STL conversion, the synergy provides better traceability and flexibility over time.

Users can access the 3DEXPERIENCE platform features and applications, while creating strategies and generating trajectories in ‘the blink of an eye’ using the AddUp Trajectory Generator. Trajectories are displayed directly in the DELMIA application, before being sent to SIMULIA applications for process simulation.