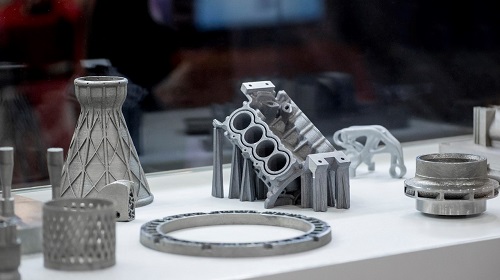

Metal 3D printing, with its ability to create complex geometries and reduce material usage, has positioned itself as a key player in the future of manufacturing. However, the sustainability of this technology is a critical aspect that must be addressed to ensure its long-term viability and positive impact on the environment.

The Sustainability Challenge in Metal 3D Printing

While metal 3D printing offers numerous advantages, it also presents several sustainability challenges that require innovative solutions.

Trends and Sustainable Solutions

The industry is actively addressing these challenges with innovative solutions that promote sustainability.

Advances and Trends From TCT Asia 2024

TCT Asia 2024 is poised to be the largest and most influential event. The exhibition will take place from May 7 to 9th, 2024, at the prestigious National Exhibition and Convention Center in Shanghai, encompassing two halls (7.1 & 8.1).

TCT Asia 2024 is a platform for showcasing the latest advancements in sustainable solutions for metal 3D printing. Key exhibitors at the event have introduced innovative practices and technologies that contribute to a greener manufacturing process. The focus on powder screening machines and other sustainable practices reflects the industry's commitment to addressing environmental concerns and promoting sustainable development.

For more information and the latest news, please follow our Facebook page.

Conclusion

The sustainability of metal 3D printing is a complex issue that requires a multifaceted approach. The industry can work towards a more sustainable future by understanding the challenges and actively pursuing innovative solutions. Developing and adopting technologies such as compact powder screening machines, enhanced dust control, utilization of recycled powders, and efficient closed-loop material management are essential steps in this direction. As the technology continues to evolve, it is imperative to prioritize sustainability to ensure that metal 3D printing becomes a truly eco-friendly and resource-efficient manufacturing method. The industry's commitment to sustainability, as demonstrated at events like TCT Asia 2024, is a promising sign of progress towards a greener and more responsible manufacturing landscape.

Foot Notes

[1] Eplus3D. The Role of SLM Metal 3D Printing in Sustainable Manufacturing. Retrieved March 29, 2024, from Eplus3D.

[2] Sertoglu, K. AMGTA publishes its first study on the environmental impact of metal 3D printing. 3D Printing Industry. Retrieved March 29, 2024, from 3D Printing Industry.

Join us at TCT Asia, connect with industry innovators as you explore the entire AM ecosystem including design, materials, hardware, software, post-processing, and quality. 10,000+ professionals will unite to hear about the latest trends, explore the latest immersive AM technologies and find solutions to their AM challenges. Make sure you are there too.

TCT ASIA 2024

Tuesday 7th May 09:00 - 17:30

Wednesday 8th May 09:00 - 17:30

Thursday 9th May 09:00 - 15:00

NECC(Shanghai)7.1&8.1H