The TCT ASIA Summit focuses on the revolutionary impact of high-speed 3D printing, showcasing how these technologies are transforming manufacturing and prototyping processes. As we prepare for this exciting summit, we anticipate in-depth discussions on the innovations shaping the future of production and design.

High-Speed 3D Printing: A Game Changer for Manufacturing

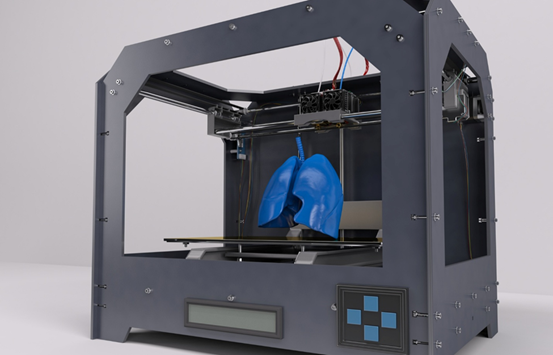

High-speed 3D printing has significantly revolutionized the way products are manufactured. By shortening production schedules through layered part creation, it allows for quicker turnarounds on prototypes and finished products. With optimized parameters such as faster print speeds, sharper resolutions, and novel materials, on-demand printing of components has become a reality. This level of flexibility facilitates rapid design iterations and accommodates intricate shapes and mixed-material items.

As the summit unfolds, we will delve into how these advancements in additive manufacturing technologies are positioning high-speed 3D printing as a means to disrupt traditional product development, evaluation, and market introduction processes. The ability to quickly bring ideas to life and test them in real-time is reshaping how industries approach innovation.

Innovations in FDM and SLA 3D Printing

Two prominent technologies transforming additive manufacturing are Fused Deposition Modeling (FDM) and Stereolithography (SLA). Both techniques have experienced significant developments aimed at increasing printing speeds and efficiency.

FDM 3D Printing: This technology involves extruding thermoplastics like acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA) using a heated nozzle, constructing 3D objects layer by layer. Popular desktop FDM printers, such as MakerBot and Ultimaker, can achieve impressive speeds exceeding 450mm/second with dual extrusion capabilities. FDM is widely used for rapid prototyping and low-volume manufacturing runs, catering to various sectors, including consumer electronics and automotive industries. Its versatility makes it an essential tool for visualizing product designs and conducting ergonomic tests before mass production.

SLA 3D Printing: Using ultraviolet light to cure liquid photopolymer resin into solid structures, SLA technology boasts build speeds of over 300 cubic millimeters per hour while maintaining exceptional resolution. Printers like Formlabs Form 3+ offer precision that is particularly well-suited for medical and dental applications. The ability to create anatomically accurate models and highly customized prosthetics underscores the promise of SLA technologies within healthcare, paving the way for improved patient care and outcomes.

Real-World Applications of Additive Manufacturing Technologies

The TCT Asia Summit provides an invaluable opportunity to explore real-world applications of these additive manufacturing technologies. Attendees will learn from industry leaders about successful implementations of high-speed 3D printing in diverse fields. From custom medical devices to unique consumer products, the potential for innovation is limitless.

Understanding how organizations leverage these cutting-edge technologies allows us to identify avenues for integration into our own operations. The insights gained from case studies presented at the summit will inform critical decisions regarding the adoption of additive manufacturing solutions tailored to specific industry needs.

Conclusion

With a strong emphasis on practical applications, cutting-edge methods like FDM and SLA, and beneficial networking possibilities, the TCT Asia Summit is expected to shed light on the future for sectors keen to capitalize on 3D printing.